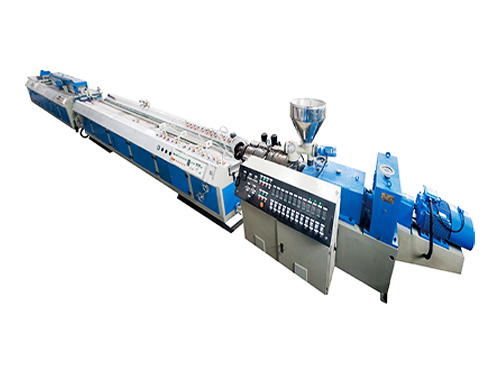

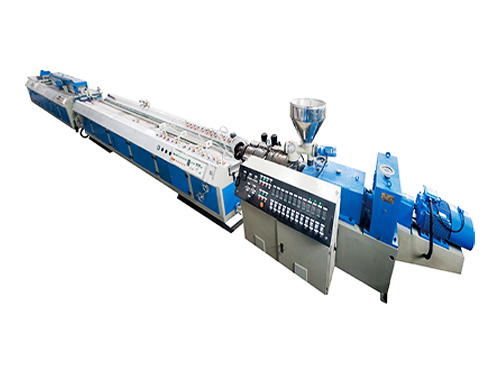

The PVC profile production line is mainly used to extrude thermoplastics such as soft and hard polyvinyl chloride, polyethylene, etc. It cooperates with the corresponding auxiliary machines (including molding heads) to process a variety of plastic products, such as film tubes, Plates, wires, belts, etc., can also be used for granulation.

The PVC profile production line has advanced design, high output, good plasticization and low energy consumption. The single screw extruder adopts involute gear transmission, which has low noise, stable operation, large bearing capacity and long life.

The screw and barrel of the production line of the small material extruder are made of high-quality alloy steel, which has been treated by nitriding, and has high strength, hardness and corrosion resistance. It is mainly composed of vacuum exhaust system, pipeline and vacuum gauge

Uses This production line is mainly used for extrusion molding of small profiles of various materials such as PCV, PE, PP, ABS, PC, etc.

The pipe extruder production line has good mechanical properties and excellent corrosion resistance. It is light in weight during use, easy to install, and requires no maintenance. Using steel as the sewer pipe of public works, it is easy to use during use. Corrosion requires frequent application of paint and high maintenance costs. Generally, metal pipes for construction and public works need to be replaced in about 20 years, while PVC pipes with good processing have a service life of up to 50 years. Therefore, the pipe extruder production line is a good plastic product with low production cost, high strength and corrosion resistance.

Pipe extruder production line This machine is equipped with a quantitative feeding device, so that the extrusion amount and the feeding amount can be matched to ensure the stable extrusion of the product. Due to the characteristics of the conical screw, the feeding section has a larger diameter, and the heat transfer area and shear speed of the material are relatively large, which is conducive to the plasticization of the material. The high shear rate enables the melt to be extruded at a lower temperature. When the screw rotates in the barrel, the PVC mixture is plasticized and pushed to the head, so as to achieve compaction, melting, mixing and homogenization; and the purpose of exhausting and dehydrating. The feeding device and screw drive device adopt frequency conversion speed regulation, which can realize synchronous speed regulation.

Mobile: 13806226918

Tel: 0512-58902000

Fax: 0512-58961949

Email: dif2008happy@163.com

Website: www.szjunte.com.cn

Address: No. 100, Lefeng Road, Leyu Town, Zhangjiagang City, Jiangsu Province