In recent years, with the requirements of light weight, energy saving and environmental protection of automobiles, more recyclable plastic pipes of materials have been used in the automotive field. This type of production line independently developed by Changzhou Jwell Pipeline Equipment Manufacturing Co., Ltd. is used for vehicle pipes, trachea and other products. By supporting the screw and barrel of different structures, it can meet the high-speed extruder of pipes or rods with PE, PP, PA, FPVC, PU, PLA, ABS and other raw materials.

Product diameter range: ID3-ID20mm, line speed: 60-80 m/min.

The PVC one-out four-speed production line has the characteristics of fast production line speed, high precision, easy operation and convenient maintenance. Minimized production waste, reduced operating costs, and reduced footprint, is the first multi-functional production line for customers.

The nylon automobile small pipeline and PVC transparent pipe production line equipment displayed on the Adsale exhibition site cooperated with world-class manufacturers, such as the Swiss Maag (MAAG) metering pump, the German FLENDER (FLENDER) reducer, and the Italian Fess. (PHASE) permanent magnet synchronous motor, Germany INOEX (INOEX) online thickness measuring device, Italy DEGA (DEGA) feeding and drying system, etc., one step closer to the online speed and overall stability. This not only reflects Jwell's strong technical integration ability as a whole, but also reflects Jwell's spirit of excellence, pursuit of excellence and continuous innovation.

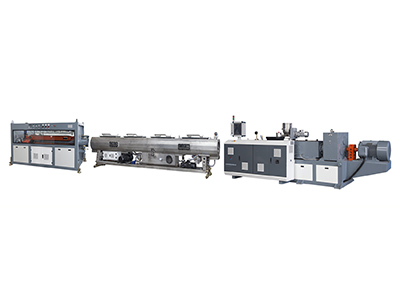

Production line composition

1. Automatic feeding and drying system

The drying effect of the equipment is achieved by the evaporation of water. In order to evaporate the water, hot air must be input into the pellets to be dried, which is different from the separate hopper used in ordinary dryers. The system works fully automatically according to the runtime program set by the timer on the control panel. To activate the system, simply adjust a dedicated button located on the digital thermostat; it monitors the system temperature via a ferroconstantan thermocouple and operates a solid state relay. When the system temperature reaches the set temperature, the heater resistor stops working; when the temperature is lower than the required temperature, the resistor starts working again. The hot air generated by the equipment is fed into the hopper through the hose, and enters the container with pellets from the radiator.

2. Feeding weighing system

SAVEOMAT single-component pellets and powder hoppers can be installed directly above the extruder discharge opening.

According to the control loop, the SAVEOMAT terminal can control the screw speed and traction speed individually or both. By accurately measuring the feeding rate and accurately controlling the weight of rice, it can reduce the consumption of raw materials, stabilize the production process, and reduce the loss of raw materials!

3. JWS65/30 single screw host

The main engine adopts B&R control system, Feiss servo motor, Flender reducer, combined with the technology and experience of various parties in the extrusion industry for many years, to provide customers with accurate control, energy-saving and efficient extrusion system.

4. Mould

The material of the mold body is 40Cr, the mold is electroplated with chrome, and the unique mold body design is used to make the material plasticize evenly, and the material discharge is stable. To achieve high speed and high output, the finished pipe has reached the first-class level in terms of wall thickness, appearance and out-of-roundness.

5. Vacuum box

The vacuum box adopts a weak vacuum design, which makes it easier to control the roundness of the pipes. The overall double-layer design prevents water from falling to the ground and keeps the site clean. The vacuum adopts frequency conversion vacuum, which is energy-saving. Observing the internal situation, the overall pipeline is uniquely designed and the hard connection is beautiful, and an air ring is installed at the rear end outlet to dry the water droplets from the vacuum box.

6. Traction cutting machine

The traction machine adopts Inovance servo motor + planetary gearbox to control the speed, the traction is stable, and the pneumatic lifting and lowering of the traction arm is easy to operate;

The cutting motor of the cutting machine adopts a servo motor, the pipe is cut to a fixed length of ±1mm, and the flying knife is cut. In addition, there is cooling water in the lower part of the knife box to cool the blade, which can be cut more than 60,000 times a day.

7. Conveying device

Combined with B&R operating procedures, this conveyor belt has a screening function, and unqualified products will be screened out and collected separately.

8. Ultrasonic thickness measurement

Features:

Provide production data (wall thickness, diameter, eccentricity, ovality)

Control wall thickness, thin point, meter weight, extrusion volume

Ensure that the production process is carried out under the condition that the wall thickness is stable and the center is centered

Material savings of 5 % or more, help with start-up and tube eccentricity

Help the operator

Provide customers with production data

Z largest inspection 7 layers, Z smallest wall thickness 0.02 mm

Optional accessories: Stapled version

Mobile: 13806226918

Tel: 0512-58902000

Fax: 0512-58961949

Email: dif2008happy@163.com

Website: www.szjunte.com.cn

Address: No. 100, Lefeng Road, Leyu Town, Zhangjiagang City, Jiangsu Province